In the pursuit of sustainable energy solutions, researchers and engineers are increasingly turning to hydrogen as a clean and versatile alternative. One key technology at the forefront of this movement is the Proton Exchange Membrane (PEM) electrolyzer. This innovative device holds the promise of unlocking the vast potential of hydrogen as a clean energy carrier. To understand its significance fully, it’s crucial to dissect the various components that make up a PEM electrolyzer.

The Heart of the System: Proton Exchange Membrane (PEM)

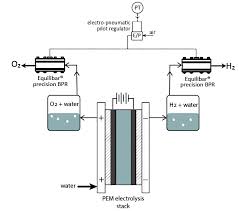

At the core of a PEM electrolyzer lies the proton exchange membrane. This membrane acts as a selective barrier, allowing the transport of protons while blocking the passage of electrons. Typically made from a specialized polymer such as Nafion, the PEM enables the electrolysis of water into hydrogen and oxygen with high efficiency. Its ability to conduct protons while maintaining separation between the anode and cathode compartments is pivotal for the electrolysis process.

Electrodes: Catalysts for Reaction

Flanking either side of the PEM are the electrodes, essential components responsible for initiating and facilitating the electrolysis reaction. The anode, typically composed of platinum or other precious metals, catalyzes the Funciones Avanzadas de Electrolizadores PEM of water molecules, releasing protons, electrons, and oxygen ions. Conversely, the cathode, often constructed with materials like nickel or cobalt, drives the reduction reaction, where protons and electrons combine to form hydrogen gas.

Current Collectors: Channeling Energy

Supporting the electrodes are current collectors, which play a crucial role in efficiently channeling electrical current to and from the electrodes. Typically made of conductive materials such as graphite or stainless steel, these collectors ensure uniform distribution of current across the electrode surfaces, minimizing resistive losses and optimizing the electrolysis process.

Cooling Systems: Maintaining Optimal Temperatures

Given the exothermic nature of electrolysis, managing temperature is critical to the performance and longevity of PEM electrolyzers. Cooling systems, often integrated into the device design, help dissipate excess heat generated during operation. By maintaining optimal operating temperatures, these systems ensure consistent performance and prevent thermal degradation of the electrolyzer components.

Gas Management: Separating Hydrogen and Oxygen

As hydrogen and oxygen gases are produced during electrolysis, effective gas management systems are essential for separating and collecting the desired product gases. Gas diffusion layers and separators enable the selective transport of gases while preventing crossover and mixing between the anode and cathode compartments. This ensures the purity of the generated hydrogen gas, ready for subsequent utilization in various applications.

Control and Monitoring Systems: Precision in Operation

To maximize efficiency and safety, PEM electrolyzers are equipped with sophisticated control and monitoring systems. These systems regulate parameters such as current, voltage, and temperature, ensuring optimal operation and preventing potential hazards such as overvoltage or overheating. Real-time monitoring of electrolyzer performance allows for timely adjustments and maintenance, enhancing overall reliability and lifespan.

Integration and Scalability: From Lab to Industry

While advancements in individual components are crucial, the true potential of PEM electrolyzers lies in their integration and scalability. Researchers are continually refining system designs and manufacturing processes to optimize performance, reduce costs, and facilitate widespread adoption across various sectors, from renewable energy storage to industrial applications.

Conclusion

As the world transitions towards a sustainable energy future, PEM electrolyzers stand as a beacon of hope, offering a clean and efficient pathway to harnessing hydrogen as an energy carrier. By dissecting and understanding the intricacies of their components, we pave the way for unlocking their full potential and accelerating the adoption of hydrogen as a key player in the global energy landscape.

Top of Form